Contact Us

+86-510-80683069

+86-510-80683069 +86-510-80683869

+86-510-80683869 sales@mascot-metal.com

sales@mascot-metal.com No.588 RenMin Road JiangYin.

No.588 RenMin Road JiangYin.

We produces a variety of tool and die steel billets of H13 (4Cr5MoSiV1), H11, 5CrNiMo, and 521 grades. They are produced with an electric arc or ladle-refining furnace, an 'RH' or vacuum degassing furnace, and a continuous or ingot casting process flow, followed by electro-slag re-melting for refining. The special steel thus produced has high purity, good combination and isotropic properties, fatigue resistance, and long life. They have been awarded a provincial prize for technological advancement and are widely used in manufacturing of mandrels, dies and rollers.

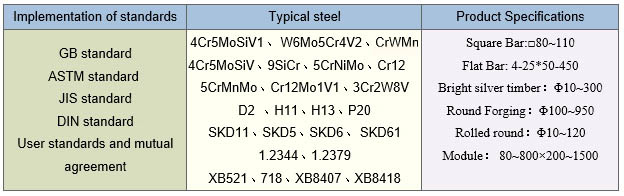

Executive Standard/ Typical steel/Specifications

Description:

(1) Delivery state: forging parts produced with continuous casting and electro-slag re-melting process; rolled as annealed, bright and quenched/tempered steel bars.

(2) Listed specifications are only typical grades; products of required specifications can be developed/produced per international, Chinese or industry standards, or based on agreements with customers.